Angela ranks 39 in the top 100 inspirational and influential women by Supply Chain Digital.

According to the publisher, Sean Ashcroft, “Supply Chain Digital’s Top 100 Women … are the most innovative, inspirational and strategically smart supply chain women on the planet.” He continues, “This list encompasses a mix of sectors from aviation, logistics, and supply chain, to tech, IT, manufacturing and F&B … These women are part of making the system work.”

She shares this year’s honors with global leaders such as:

Angela would like to thank her many supporters and staff for being a part of these honors.

“Being recognized by so many different organizations this year is such an honor. I couldn’t do any of this without the great staff at AGT Global. They truly make it happen. Thank you everyone at AGT. You keep my world turning.” ~ Angela

We don’t know what we got, until … we can’t find it in the store!

With some of the biggest US holidays happening soon – we all need to embrace our personal-logistics superpowers.

In the world of logistics, many contributing factors go into our day-to-day lives. Fortunately, most people never think about how important the supply chain is to their everyday lives – – until we find empty shelves or your package arrives two weeks late.

We’re here to help guide you through the 2021 holiday season.

What are some of the fears currently being spread around the internet? Let’s start with the one that could ruffle some feathers …

No Turkey for Thanksgiving?

Fortunately, this scare doesn’t seem to be real. The mumble of a turkey shortage was first felt in Canada for Canadian Thanksgiving – and although the turkey processors of Canada have been hit hard, reports from the Turkey Famers of Canada state, “Turkey farmers work together under supply management to match what they grow with what consumers need and want. The industry is able to prevent surpluses or shortages in the market by planning production, ensuring Canadian consumers have access to a reliable supply of high quality Canadian turkey products at reasonable prices, year-round.”

Image by RODNAE Productions

Stories from Toronto to Newfoundland all found that after a brief start of limiting the number of birds/customer — the supply was enough to meet the demand.

This is good news for those of us on the other side of the border. The US seems to mirror the current turkey production status of Canada. We have reduced production and, unfortunately, have laid-off workers and shut down turkey plants. So, a surge in demand looks like something our supply chain is ready for – as is the turkey production industry.

It might not be precisely the bird you want – but there are turkeys for the taking. Due to smaller family gatherings and reduction in production – smaller and fresh birds may be more challenging to grab up at your local grocer. Still, there is no expected overall turkey shortage.

Don’t be afraid to Gobble up those birds at the store; there should be enough for everyone.

Make sure to check back for some of our favorite recipes!

Advice: The good thing about trucking and logistics is that once you prove yourself, you’re treated with respect. If you maintain your integrity, if you promise something and you continue to deliver, others start to not pay attention to the fact that you are a woman. ~ Angela Eliacostas

Angela Eliacostas is recognized by Inbound Logistics as one of seven outstanding women in supply chain and logistics. This is an honor coming from such a widely recognized and respected publication.

https://www.inboundlogistics.com/cms/article/7-outstanding-women-in-supply-chain-and-logistics/

Outage planning can be a very complicated process that requires the coordination of available resources, tight scheduling, consideration of safety issues, and the satisfying of the seemingly endless regulatory and technical requirements. Hundreds — sometimes even thousands — of contract workers are brought on site to support the outage, allowing the utility to work continuously, around the clock, until the outage is complete. Scheduled outages are often planned up to a year in advance and can sometimes last for months.

In recent years, cost overruns for planned outages at some utilities have dramatically exceeded their original set-asides for that work. Whether you just completed an outage, are in the midst of one, or in the planning process, here are 5 things to consider before planning your next scheduled outage.

What are your biggest logistical challenges? There are a number of logistical challenges that may come into play during an outage. One example would be geographical challenges. Is your facility in a geographically isolated location? When a customer or its vendor is in a geographically isolated area, capacity may need to be sought out at the nearest metropolitan area which, dependent on region, may encounter delays in responding to a shipper and/or consignee. Also, geographically isolated areas are impacted by lack of equipment to support pickups and/or deliveries and may not be accessible by truck or plane.

What deployable resources do you have? Many of the decisions will be heavily influenced by the number of resources you have available. Do you have a small team? Are you in a situation where many of the outage tasks and responsibilities need to be outsourced to vendors? At AGT Global Logistics we train our operations team to be prepared to support stations in outages by reviewing historical data and lessons learned from past outages, and insights gained from pre-outage meetings with members of the supply chain team. In order to sufficiently support a station during its outage, 24/7 operations and additional capacity are critical, especially in the event of something unexpected arising.

What are some standard pain points with outages? Which areas has your business identified for improvement? Has your organization identified areas of improvement for the next scheduled outage? If so, it’s important to think about what steps are being taken to address those key areas that have been identified prior to the outage. At AGT, when we work with a client on a scheduled outage we use insights gained from a briefing meeting, these little tidbits are often invaluable pieces of information that we hold onto and consider as we move through the planning and execution process.

What does success look like for your outage? Success can come in many different forms, it’s important to determine what is most important to you and your organization. Is staying on timeline most important? Is not going over the allocated budget a key outcome? Is your outage a high-risk operation where safety of all workers is paramount? Whatever your goals are, its critical that you set a benchmark as to what success would be and gear all efforts towards reaching that goal.

Are there any new laws or regulations that will impact your outage planning or execution? As mentioned in the opening, there are endless regulatory and compliance issues that can impact an outage. It’s important to stay up to date on new laws and regulations to assure your outage won’t be affected, and if it is, being informed will allow enough time to adjust and prepare for impending changes. One example of this is the recent ELD mandate. With electronic logs, delays at the shipper and/or consignee can result in delays to current transit or subsequent transportation. With efforts to load and unload in a timely manner, and being prepared with appropriate resources from shippers and consignees, the effect can be lessened. Not understanding the new ELD mandate and the impact it will have could prove to be a costly oversight.

There are certainly many other factors to be taken into consideration but starting with these five will put you on the path to a successfully planned outage.

Regardless of where you land on the debate regarding the ELD mandate or its merits, the reality is that the time for implementation has arrived and transportation and logistics professionals must adhere to these new measures.

As you all know, the efforts made to delay or halt the decision on ELD’s were ultimately unsuccessful, and the smartest thing anyone in the industry can do at this point is to be knowledgeable about the new regulations and be prepared for the effects its implementation will have on us all.

We know two things for sure:

1. The effects of the ELD regulations will ripple across all sectors of the trucking and logistics industries

2. The amount of information on this topic is pretty staggering

With those points in mind, we’re going to break it up into three small sections and provide insights on how this mandate will impact third party logistics providers, Drivers, and the supply chain as a whole.

Third Party Logistics Providers

First, lets discuss the effect that the new regulations will have on third party logistics providers like AGT.

● In order to play a part in proper use of Hours Of Service (HOS), 3PL’s will need to work with carriers to properly schedule and communicate the pickup and delivery schedule to the shippers and receivers.

● As productivity will decrease, 450-600 mile one day trips will result in 2 day trips and 900-1200 mile 2 day trips will likely become 3 day trips – as a result rates will increase.

● AGT plans on strategically working with carriers of various fleet sizes and markets to mitigate the effects of the ELD mandate on shippers & 3PL’s.

Drivers

This is where the rubber literally hits the road, and our drivers will certainly feel this mandate the heaviest out of all parties involved.

● Though the intended impact of the ELD Mandate is to increase the safety of drivers by reducing “driver fatigue,” many still face the daunting decision of whether to comply or cease operations altogether.

● There will be many drivers who have been moving shipments with accelerated transit who will now be forced to operate according to legal hours. This will impact the frequency with which a truck is available for use and change how long it takes some shipments to deliver.

● With these new hours restrictions, it is important for carriers to work with shippers and 3PL’s to make sure loads are ready and driver selection is based on best HOS for that specific trip.

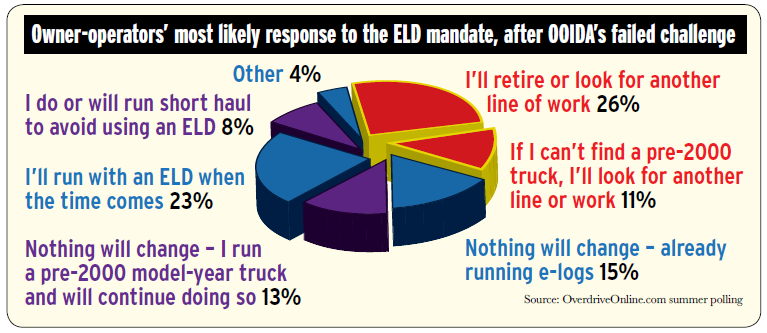

Here’s some of the responses from owner-operators’ when asked about the ELD mandate in a recent poll:

Overall Supply Chain

Lastly, let’s finish by pointing out what this new mandate will do to the overall supply chain.

Communication between all parties will be critical to the efficiency of supply chains. HOS will become a hot commodity and will need to be maximized.

Rate increases are also likely to impact shippers/receivers who have slow loading or unloading times. This is something that can’t be overlooked. Shippers and receivers need to be prepared with resources to load & unload shipments.

● Shippers that are prepared with resources to load, all necessary paperwork completed and an accurate time for loading will prevent delays resulting in less wasted drivers HOS.

● In that same respect, if the receiver is also prepared, the driver can promptly unload the freight, possibly reserving HOS for the next shipment and allowing for more capacity to other shippers and/or 3PL’s.

● Delays in loading and unloading could now be more costly than ever before.

While the ELD mandate is not “the end of the world” it does create a number of new pitfalls and considerations that need to be navigated carefully if your company is going to thrive in the new logistics landscape – particularly if you own/operate/manage a smaller fleet.

We hope this information was helpful. Please feel free to contact us with any questions you may have.